Understanding Welding Health Risks and Prevention Tips

As a professional welder, I know how vital it is to keep myself safe and healthy at work. Welding can expose us to many dangers, like breathing problems and eye damage from arc flashes.

But, by knowing these risks and taking the right steps, we can lessen the harm it can cause.

In this guide, I'll cover the key health risks of welding. I'll teach you how to spot and deal with these dangers.

We'll look at everything from short-term issues like metal fume fever to long-term problems like chronic breathing issues. I'll also share tips on choosing the right protective gear and using good ventilation to keep you safe.

"Discover essential safety information about welding health risks and learn effective prevention strategies to protect yourself while working in welding operations."

Key Takeaways

- Welding can expose workers to a variety of health risks, including respiratory irritants, vision-impairing arc flashes, and metal fume fever.

- Understanding the short-term and long-term health effects of welding exposures is crucial for prevention and mitigation.

- Selecting the right personal protective equipment, such as respiratory protection and eye/face shields, is essential for welder safety.

- Proper ventilation systems are a critical component in reducing exposure to welding fumes and gases.

- Regularly scheduled medical examinations and exposure monitoring can help identify and address health issues early on.

The Fundamentals of Welding Health Risks

Welding is key in many industries, but it poses serious health risks. These risks include welding fumes, arc eye, and respiratory hazards. It's important to know and tackle these dangers.

Common Types of Welding Exposures

Welders face many exposures, such as:

- Toxic fumes from welding can have harmful metals like lead, cadmium, and chromium

- Intense UV radiation from the welding arc can harm eyes and skin

- Hazardous gases, like carbon monoxide and nitrogen oxides, released during welding

- Noise from welding equipment, which can cause hearing loss over time

Short-term vs. Long-term Health Effects

Welding exposures can have both immediate and lasting health impacts. Short-term effects include metal fume fever, arc eye, and respiratory irritation. Long-term effects can be chronic lung diseases, neurological disorders, and even cancer.

Risk Factors in Different Welding Processes

The risks for welders differ based on the welding method. For instance, stainless steel welding poses a higher risk of chromium and nickel exposure. Meanwhile, aluminum welding may lead to respiratory hazards from fumes.

It's vital to grasp these basic welding health risks. This knowledge helps protect welders and ensures a safe workplace.

Respiratory Hazards from Welding Fumes and Gases

Welding is key in many industries but comes with big health risks. The fumes and gases from welding can harm welders and those nearby. It's important to know these dangers to keep workers safe.

Welding fumes mix metals and other particles that can be breathed in. They may have harmful stuff like hexavalent chromium, manganese, and cadmium. These can cause lung problems, including lung irritation, inflammation, and lung cancer. Welders might also get metal fume fever, feeling like they have the flu.

Welding also releases gases like carbon monoxide, nitrogen oxides, and ozone. These gases can irritate the respiratory system, make it hard to breathe, and even cause asphyxiation in bad air.

The dangers from welding depend on the process, materials, and how long you're exposed. For example, stainless steel welding can lead to lung cancer because of chromium and nickel. Using good ventilation and PPE is key to keeping welders and others safe.

| Welding Process | Potential Respiratory Hazards |

|---|---|

| Mild Steel Welding | Iron oxide, manganese |

| Stainless Steel Welding | Chromium, nickel, hexavalent chromium |

| Aluminum Welding | Aluminum oxide |

| Brazing | Cadmium, zinc oxide |

It's vital to tackle the respiratory dangers of welding to protect workers. Good ventilation, the right PPE, and health checks can make the workplace safer for everyone.

Metal Fume Fever: Recognition and Prevention

Welding galvanized steel or zinc-containing materials can lead to metal fume fever. This is a temporary illness that feels like the flu. Knowing the signs and how to prevent it is key to staying safe while welding.

Symptoms and Early Warning Signs

Symptoms of metal fume fever include a metallic taste, dry throat, chills, fever, muscle aches, and tiredness. These start 4-12 hours after exposure and last 12-48 hours. Spotting these signs early is crucial for quick medical help and recovery.

Treatment and Recovery Protocols

Most cases of metal fume fever get better with rest and drinking water. But, severe cases might need medical help. Doctors may give pain relievers, anti-inflammatory drugs, and supportive care.

Prevention Strategies

- Make sure there's good airflow and use the right protective gear, like respirators, to cut down on fume and gas exposure.

- Start a health monitoring program to catch metal fume fever and other welding health problems early.

- Teach workers about metal fume fever, how to treat it, and how to prevent it. Stress the need to report symptoms right away.

- Think about using different materials that don't have zinc or use stainless steel welding products to lower metal fume fever risks.

Knowing about metal fume fever's symptoms, treatment, and prevention helps keep welders and employers safe. Being careful and following safety rules are essential to avoid this welding illness.

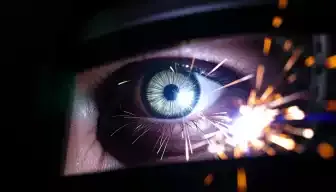

Arc Eye and Other Vision-Related Dangers

Welding is a risky job, especially for your eyes. The bright arc eye, harmful smoke, and radiation can damage your vision. It's important to take the right precautions.

Arc eye, also known as welder's flash or photokeratitis, is a painful condition. It's caused by UV radiation from welding. This can lead to temporary blindness, inflammation, and eye pain.

Welders face other eye problems too, like:

- Welding smoke can irritate and damage eyes over time.

- Infrared radiation from the arc can cause cataracts and lens problems.

- Hazardous gases like ozone and nitrogen oxides can also harm the eyes.

To protect your eyes, wear the right PPE. This includes a welding helmet with the correct lens shade and safety glasses or goggles. Good ventilation and air filtration help reduce smoke and harmful substances.

"Welding can expose your eyes to intense radiation and harmful fumes, so it's essential to take eye protection seriously. Neglecting this can lead to long-term vision problems."

By knowing the risks and taking precautions, welders can protect their eyes. This reduces the chance of arc eye and other vision problems.

Long-term Effects of Welding on the Respiratory System

Welding is key in many industries, but it can harm your lungs over time. It's important to know the risks to keep workers safe and healthy.

Chronic Bronchitis and Lung Disease

Long-term exposure to welding fumes can cause chronic bronchitis. This makes it hard to breathe and can lead to coughing and mucus buildup. Welding also raises the risk of lung diseases like pulmonary fibrosis, which scars the lungs.

Cancer Risk Factors

Welders face a higher risk of lung cancer. This is because welding fumes contain harmful metals like hexavalent chromium and nickel. Breathing in these toxins can damage the lungs and increase cancer risk.

Preventive Medical Screening

- Welders should get regular lung function tests, like spirometry and chest X-rays, to check their health.

- They should also have comprehensive medical exams, including lung cancer screenings, as part of a health program.

- Early detection and treatment are key to managing welding's long-term lung effects.

Knowing the risks of welding and taking preventive steps is crucial. Employers and workers must work together to keep the workplace safe and healthy. Protecting respiratory health is vital for the welding industry.

Special Considerations for Aluminum and Stainless Steel Welding

Welding aluminum and stainless steel comes with special health risks. These metals can release harmful fumes and gases. These can be dangerous to a welder's lungs.

Welding aluminum can expose you to manganese. This heavy metal can harm your brain if you breathe too much of it. Stainless steel welding, meanwhile, can lead to nickel exposure. Nickel has been linked to lung cancer.

To stay safe, welders need to wear the right protective gear and use good ventilation. They should also get regular health checks and monitor their exposure levels. This helps keep them healthy over time.

| Welding Process | Potential Health Risks | Key Preventive Measures |

|---|---|---|

| Aluminum Welding | Manganese exposure, respiratory issues | Proper ventilation, use of respiratory PPE, regular medical screenings |

| Stainless Steel Welding | Nickel exposure increases cancer risk | Adequate ventilation, use of respiratory PPE, regular medical check-ups |

Knowing the risks of aluminum and stainless steel welding helps welders stay safe. By taking the right precautions, they can avoid harmful exposures. This protects their health for the long term.

"The key to safe welding with aluminum and stainless steel is proactive prevention and vigilant monitoring of exposures."

Essential Personal Protective Equipment for Welders

As a welder, your safety is key. Wearing the right personal protective equipment (PPE) is vital. It keeps you safe from harm on the job. Let's look at the must-have gear for welders, from masks to body shields.

Respiratory Protection Systems

Welding fumes and gases can harm your lungs. To avoid this, welders need the right respiratory protection. This includes respirators with the right filters and cartridges. It's important to make sure they fit well and to change the filters often.

Eye and Face Protection

The bright light and sparks from welding can hurt your eyes and face. You must wear eye and face protection, like welding helmets or goggles. They should have the right shade lenses to block harmful rays. These tools are made for welding to keep you safe.

Body Protection Guidelines

The heat, molten metal, and sparks from welding can be dangerous. To stay safe, wear protective clothing that covers your whole body. This includes flame-resistant coveralls, leather gloves, and strong, steel-toed boots. These safety precautions help prevent burns, cuts, and other injuries.

Buying top-notch personal protective equipment (PPE) is crucial for welders' health and safety. By focusing on masks, eye and face shields, and full-body coverage, welders can reduce job risks. This way, they can stay healthy and safe while working.

Proper Ventilation Systems and Requirements

Welding can release harmful fumes and gases. These can be dangerous if not managed well. It's important to have good ventilation systems to keep welders safe.

Understanding Ventilation Systems

There are two main types of ventilation systems for welding. General dilution ventilation spreads out contaminants in the whole area. Local exhaust ventilation (LEV) catches fumes right where they're made.

Importance of LEV Systems

LEV systems are the best way to handle welding fumes. They have hoods near the welding area to pull in and remove contaminants. It's key to install and keep LEV systems in good shape to work well.

Ventilation Requirements for Confined Spaces

Welding in tight spaces is harder. Ventilation needs to be stricter to avoid dangerous fumes. Special systems, like portable LEV units, might be needed to keep the area safe.

Having the right ventilation systems is crucial for welder safety. Employers should focus on ventilation to protect their workers. This helps prevent health problems from welding.

"Proper ventilation is the most effective way to control welding fumes and gases, safeguarding the health and well-being of welders."

Health Monitoring and Surveillance Programs

Health monitoring and surveillance programs are key to protecting welders. They help identify and reduce health risks in the workplace. These programs are designed to keep welding professionals safe and healthy.

Regular Medical Examinations

Welders need to have regular medical exams. These exams check their overall health and look for signs of health problems. Tests like lung function tests and blood work help find issues early.

Exposure Monitoring Methods

Monitoring exposure to harmful substances is also important. This helps ensure workers are not exposed to too many harmful fumes and gases. It also guides the use of safety gear and better work practices.

Record-Keeping Requirements

Keeping detailed records is crucial. Employers must record medical exams, exposure results, and any health incidents. This helps follow safety rules and improve health and safety over time.

"Effective health monitoring and surveillance programs are essential for protecting welders and ensuring their long-term well-being."

Strong health monitoring and surveillance programs protect welders. They help keep the workplace safe and productive. This is good for everyone involved.

Workplace Safety Standards and Compliance

As a welder, knowing the safety rules is key. The Occupational Safety and Health Administration (OSHA) helps make sure we work in a safe place. This is true for all welders in the United States.

OSHA has clear rules for welding safety. These include wearing the right protective gear and using good ventilation. Following these rules is not just the law. It's also essential for keeping our workplaces safe and healthy.

Employers must follow OSHA's safety standards. This means handling welding gases correctly and monitoring exposure. By working together, we can keep welders safe and reduce the dangers of our job.

FAQ

What are the most common health risks associated with welding?

Welding can harm your health in many ways. Exposure to welding fumes can cause breathing problems like metal fume fever and lung disease. It can even lead to cancer. Eye injuries, skin burns, and electric shock are other dangers.

What are the long-term effects of welding?

Long-term exposure to welding fumes can cause serious health issues. These include chronic respiratory diseases and lung cancer. It can also affect your fertility and lead to other long-term health problems.

How can welders protect themselves from the health risks of welding?

To stay safe, welders should wear proper protective gear. This includes respirators, safety glasses, and protective clothing. Good ventilation and following safety rules are also key. Regular health checks can catch problems early.

What are the health risks of welding galvanized steel?

Welding galvanized steel is risky because of the zinc coating. It can cause metal fume fever, which feels like the flu. It's important to have good ventilation and wear the right gear when working with galvanized steel.

Can welding cause lung cancer?

Yes, welding fumes can increase lung cancer risk. This is especially true for fumes with hexavalent chromium. Regular health checks and monitoring for lung disease are important.

What are the short-term health effects of welding?

Welding can cause eye irritation and arc eye, as well as metal fume fever and breathing problems. These can happen right away or during short tasks. Wearing the right gear and using good ventilation can help.

How does welding affect the eyes?

Welding's UV radiation and bright light can cause arc eye or welder's flash. This can lead to blindness, eye pain, and swelling. It's vital to wear proper helmets and face shields to protect your eyes.

What are the health risks of underwater welding?

Underwater welding is risky because of toxic fumes, decompression sickness, and electric shock. It's crucial to follow strict safety rules, get special training, and use the right gear.

How can welders reduce their exposure to welding fumes?

To cut down on fume exposure, welders should use local exhaust systems and work in well-ventilated areas. Wearing respirators and keeping equipment in good shape also helps.

What are the most common health and safety risks associated with welding operations?

Welding poses many risks, including fume and gas exposure, fire and explosion dangers, electric shock, and physical injuries. It's important to use safety gear, follow safety rules, and get proper training to avoid these risks.